Saturday, June 28, 2008

Water plumbing for Laminova oil cooler

Friday, June 20, 2008

Engine Inlet Temperature

So, I pulled up one of the data logs from my PLX Devices R-500, since I have it tapped into the air temperature sensor on the throttle body. This sensor measures the temperature of the charge air entering the engine, after it has been cooled by the intercooler. I have to admit that I expected the temperature to be in the range of 70 to 90 degrees since after going for an enthusiastic drive, the throttle body and plenum chamber are too hot to keep my finger on.

The picture above is a screen grab of the PLX Logger software charting the data in 2D. It's a bit rough... I've been having trouble getting reliable RPM data from the engine speed tap and so this needs to be multiplied by 5 to give the correct engine speed (I think I'm going to tap into one of the ignition timing wires instead). The MAP values are also a little bit out. However, the chart gives a good enough idea of what's happening and the temperature values are correct.

What you see is that at idle, when the car is stationary and no cooling air is flowing across the intercoolers, the inlet temperature is up around 50 degrees Centigrade. It's important to realise that the ambient temperature when these reading were taken was around 5 degrees Centigrade, so pretty cool. As soon as the car starts moving, the inlet temperature rapidly starts to decrease to a steady state around 30 degrees above the ambient temperature. When the car is driven hard at around 380 seconds, there are significant peaks in the inlet temperature. The temperature is quick to fall back to a steady state less than 40 degrees Centigrade.

I still need to capture some log data for summer temperature, but I suspect that steady state with an ambient temperature around 30 degrees Centigrade will be about 70 degrees Centigrade. This is less than I expected and my conclusion from this is that, unless the car is going to be raced on a track where the engine is kept at full load for a long time, then there's no huge benefit to changing out the stock intercoolers if the car is being run with 1.20 barg inlet pressure. Bear in mind that if the car is run on the track, there will be a good flow of air all the time over the intercoolers helping to keep them cool. The highest inlet temperatures are occurring when the car is stationary or moving slowly and increasing the intercooler size is not going to help this.

What I'm therefore thinking of doing is adding a cooling fan behind each intercooler, connected to the water radiator cooling fans. These fans generally only activate when the car is moving slowly or stationary so would be a good control for the intercooler fans. This should then keep the intercoolers at a relatively low temperature when driving around town for example, or when the car is cooling down after a hard drive.

Tuesday, April 01, 2008

Rubber Update

It seems that Maserati made an adapter kit for the non-ABS Ghibli in order to fit the later designed package from the GT variant. I also discovered that the design of the ABS and the subsequent GT cars are both different, which surprised me.

Fortuitously, Jorrit came across a Ghibli non-ABS subframe fitted with the adapter rings to fit the new parts from a GT car. Since he suspects that the second hand subframe is not completely straight, he's going to remove the adapters from this and fit them onto my good subframe and then order parts 1 to 7 in the drawing below. Since the rubbers from this GT group are cheap, I'll order a spare couple and take some measurements from these and try and get an equivalent poly part sourced.

This set up should make the front of my car feel stiffer and should help prevent rubbing my tires against the wheel arch when I corner hard. Talking of which, I checked my front tire size to jog my memory and indeed I fitted a pair of 225x40 tires on the front. Next time I'll fit some 225x35 which should prevent future rubbing... I went with the larger wall height to try and raise the front of the car a bit, but I think 40 was a little excessive in hindsight.

So, I'll be booking my car in with Jorrit shortly to do the following:

- Upgrade the front bushings to GT spec.

- Fit the Mocal oil/water heat exchanger.

- Replace the pin in the driver's side door hinge.

- Measure up the exhaust so that I can order some catalysts.

Hopefully I can get this sorted next week and ready for a drive to Mosel in Germany at the end of the month!

Sunday, January 20, 2008

Preparing for the spring

I've therefore been researching into oil cooling. Initially, I was looking into fitting an efficient air cooler and locating it in front of the engine cooling radiator, in a similar fashion to the Modena performance air/oil cooler pictured here (from Enrico's Maserati pages). It's the large silver coloured one in the centre. I actually think this cooler is a bit over the top, since an efficient cooler of half this size should be sufficient, although I think this Modena prepared car is awaiting a V8 engine conversion. Also, I don't think it's very efficient mounting the cooler with such a large gap between the rear of the cooler and the front of the water radiator, since the exhaust flow from the oil cooler will not flow nicely through the radiator.

I've therefore been researching into oil cooling. Initially, I was looking into fitting an efficient air cooler and locating it in front of the engine cooling radiator, in a similar fashion to the Modena performance air/oil cooler pictured here (from Enrico's Maserati pages). It's the large silver coloured one in the centre. I actually think this cooler is a bit over the top, since an efficient cooler of half this size should be sufficient, although I think this Modena prepared car is awaiting a V8 engine conversion. Also, I don't think it's very efficient mounting the cooler with such a large gap between the rear of the cooler and the front of the water radiator, since the exhaust flow from the oil cooler will not flow nicely through the radiator. So, I was researching into fitting an sandwich adapter between the oil pump and the oil filter to facilitate fitting hoses to the front mounted oil cooler and had managed to source a second hand Maserati part with built in thermostat, pictured here. This little device only sends oil to the cooler after it has reached a certain temperature (around 80 degrees C) in order to warm the oil up to operating temperature as quickly as possible, otherwise the oil will be too cool and hence quite viscous.

So, I was researching into fitting an sandwich adapter between the oil pump and the oil filter to facilitate fitting hoses to the front mounted oil cooler and had managed to source a second hand Maserati part with built in thermostat, pictured here. This little device only sends oil to the cooler after it has reached a certain temperature (around 80 degrees C) in order to warm the oil up to operating temperature as quickly as possible, otherwise the oil will be too cool and hence quite viscous.While discussing my options with the Bi-turbo forum on Yahoo, one of the members talked about the oil/water cooler he has fitted to his Maserati Ghibli Cup and subsequently sent some pictures of the cooler fitted to his car. After researching the cooler (it's a Mocal Laminova cooler), the benefits, particularly for my application, were clear.

A water/oil cooler does not need a thermostat and warms the oil up to operating temperature much quicker than an air/oil cooler. This is because the water/oil cooler is actually a heat exchanger and the water cooling is very effective at taking heating from the engine and therefore warms up quickly. The water/oil cooler then transfers this heat into the oil, hence warming it up quickly. I often drive drive reasonably short journeys in my car (twenty minutes) which is only just long enough to get the engine properly warmed up. Therefore, anything I can do to warm it up quicker is certainly a bonus.

A water/oil cooler does not need a thermostat and warms the oil up to operating temperature much quicker than an air/oil cooler. This is because the water/oil cooler is actually a heat exchanger and the water cooling is very effective at taking heating from the engine and therefore warms up quickly. The water/oil cooler then transfers this heat into the oil, hence warming it up quickly. I often drive drive reasonably short journeys in my car (twenty minutes) which is only just long enough to get the engine properly warmed up. Therefore, anything I can do to warm it up quicker is certainly a bonus.Although the water warms up the oil quickly, the water cooling on the Ghibli is very effective at maintaining the water temperature at around 90 degrees C, even in extreme use. The idea of the water/oil cooler is that the fluid temperatures of the oil and water remain about the same, which means that the oil temperature should be maintained around 90 degrees, which is about perfect!

In order to fit the water/oil cooler, I'll have to fit a remote oil filter and an adapter plate to the oil pump to facilitate running lines to the remote filter. The cooler itself will be mounted behind the water radiator, spliced into the line that takes cool water from the radiator back into the engine block. In the drawing, this will mean rotating part 34 clockwise about 90 degrees, fitting in the Mocal cooler, then installing a new 90 degree elbow to face upwards, then installing part 6 (will have to flip it round) up and into part 5, which will have to be rotated 90 degrees anti-clockwise.

In order to fit the water/oil cooler, I'll have to fit a remote oil filter and an adapter plate to the oil pump to facilitate running lines to the remote filter. The cooler itself will be mounted behind the water radiator, spliced into the line that takes cool water from the radiator back into the engine block. In the drawing, this will mean rotating part 34 clockwise about 90 degrees, fitting in the Mocal cooler, then installing a new 90 degree elbow to face upwards, then installing part 6 (will have to flip it round) up and into part 5, which will have to be rotated 90 degrees anti-clockwise.The parts are made by Think Auto in the UK, who are not proving to be the most effective with e-mail correspondence. However, I have managed to get a quote off them for the parts I require... the water Laminova is not cheap, but the other parts are pretty reasonable and Jorrit at Auto Forza can get all the hose and fittings tailor made for me.

I'm hoping to get it installed within the next couple of months.

Thursday, December 27, 2007

Sneak preview of PLX Devices R-800

As you may have read, I'm not particularly impressed with the PLX Devices R-500 unit that I'm currently fitting to my car. The screen is awful and it's not particularly user friendly, plus it's a pain to mount in the dash since it's a bit on the large side and the thick cable that extrudes out the side of the device is not very malleable and is therefore hard to route.

As you may have read, I'm not particularly impressed with the PLX Devices R-500 unit that I'm currently fitting to my car. The screen is awful and it's not particularly user friendly, plus it's a pain to mount in the dash since it's a bit on the large side and the thick cable that extrudes out the side of the device is not very malleable and is therefore hard to route.However, searching around on the internet, I've seen references to a replacement that PLX Devices are about to bring out, which annoys me even more since I only bought the R-500 this year and it's already being replaced. However, reading on the PLX Forums, it seems that they may offer some rebate to customers of the R-500, so I might try and upgrade it.

Monday, September 10, 2007

Back at the Dyno

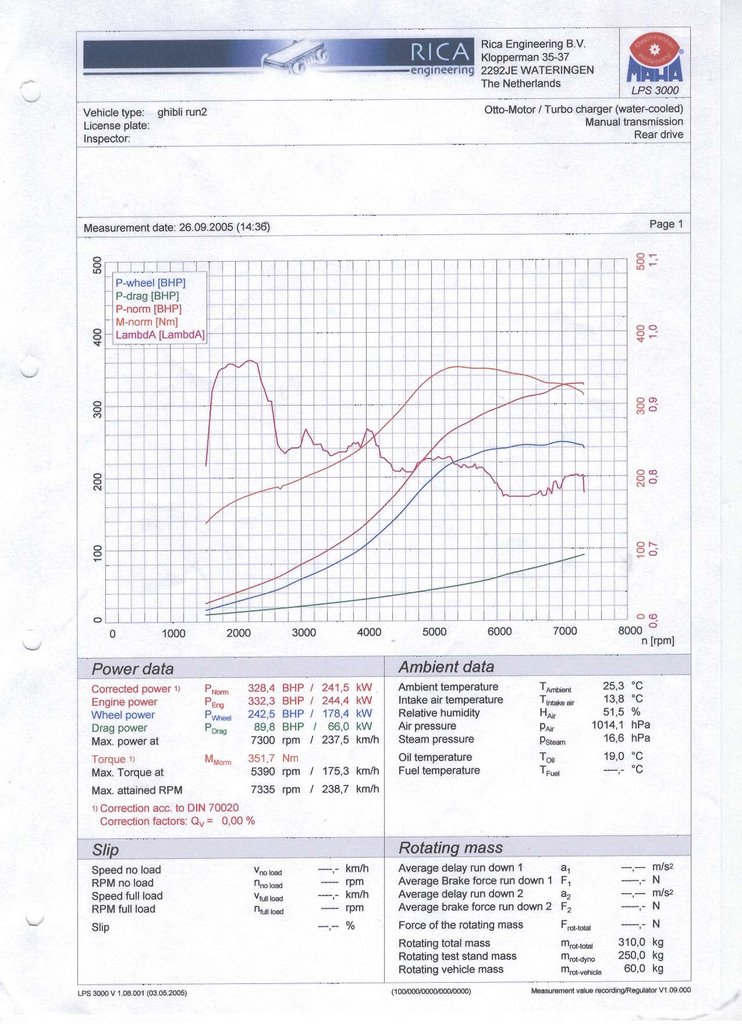

In the meantime, I've been back to the dyno and to prove it I made a very short video.

The dyno results are below, with the bold lines the new results overlaying the previous results.

As you can see, I've dropped the boost pressure a little which results in a lower peak torque and less agressive ramp up. However, as a result I now have a longer flat section from 4000 rpm to about 5,500 rpm.

Overall performance can be determined by calculating the area beneath the curves... in mathematical terms, if you integrate the curve you'll calculate the actual work done. So although the new curve is not as peaky, across the rev range it's more effective, which should translate as being quicker on the road.

I think there's still some scope to tweak the inlet pressure a little, but it won't yield any big improvements. There's something fundamental preventing me from getting more power out of this engine and I can't quite put my finger on it. Fuelling is not the issue... if anything it's running too rich at the top end, but the chip tuner prefers this since it's much less likely that the engine is going to fail. But it shows that the current injectors are more than up to the job.

So if there's enough fuel, is there enough air? Air supply to the compressors is not the issue, since last time I was at the tuners I did a run with no air filters and there was hardly any difference (so I think the air filters I have fitted are more than good enough). So, maybe I'm getting a significant amount of pressure leak between the compressors and the inlet manifold? To check this I'll need to place a pressure gauge near to the outlet of the compressor and compare this with the pressure at the plenum chamber. It could be that the turbos are having to work very hard to maintain 1.20 bar, which is effecting their efficiency.

Another simple thing to try is to connect the stock boost solenoid... although it won't be controlling the inlet pressure, it's absense may be alerting the ECU and knocking it into safe mode. I don't think the Ghibli ECU has an error check circuit for this like modern cars, but I don't know, so it's worth checking it.

If it's not air supply then it has to come down to timing. I certainly think this is what is preventing me going above 1.20 bar, but I think I should be getting better performance at 1.20 bar, so I'm not going to go down this route yet. I think I should be able to get 360 hp out of this engine at 1.20 bar, so I need to find out what's preventing this before looking at changing out the distribution system.

So... the sooner I install the PLX data logger the better I think.

Tuesday, July 03, 2007

Garage appointment booked

Not much to report other than the new exhaust should be delivered by the end of this week (Larini seems to be a bit stretched at the moment, since they told me two to three weeks delivery but are taking more like four to five).

All the parts for changing out the bumpers have arrived at the garage except for some of the the adapter fittings (since the new bumpers are designed to fit on an ABS Ghibli, which has a slightly different fitting to the non-ABS cars), but hopefully these will arrive before the end of the week. I also noticed that the rubber elbow pipe leading to my driver's side intercooler was looking a bit cracked and have therefore ordered a new one... which is still yet to arrive, but Jorrit has a decent second hand one in his store which he'll fit if the new part hasn't arrived in time.

Here's a summary of the work that's hopefully getting done:

- Replace bumpers front and back (including re-spray).

- Roll out dent on front left wing.

- Roll out dent in floor in driver’s side foot well.

- Change out cracked rubber elbow into left intercooler.

- Fasten boost solenoid valve (the original screw has fallen out).

- Fabricate and fit new fixing brackets for air boxes.

- Get the car APK tested (road worthiness test).

- Fit new exhaust.

- Fit wide-band lambda probe (including resistor) and wire in data-logger to ECU wiring harness (just the power and lambda probe for now). I need the pin diagram for non-ABS Ghibli (think it's the same as for a 224?). Once I have the pin diagram then I can wire in the other signals. Install the exhaust gas temperature probe on the exhaust and run the cables into the cockpit along with the lambda probe cables. I think there’s a spare port on the exhaust, otherwise will have to drill a hole and weld one on? It’s a 1/8” NPT fitting.

- The voltmeter still stops working so will see if it can be fixed? Maybe a faulty earth connection?

- Check engine timing; the car is loosing power above 4000 rpm, which may be an indication of problems with the distributor or valve timing. I’m convinced the car is loosing 10-20% power above 4000 rpm and since the fuelling looks fine from the last dyno (although the wideband lambda will be able to confirm this) the likely culprit is either air flow/temperature (changing the exhaust will help determine this) or timing (I’ve no reason to suspect that the ECU timing is incorrect since it’s not been re-programmed since the car was running well and producing 330 hp). So I think it’s a mechanical problem (unless one of the sensors to the ECU is malfunctioning, but if I get the data logger setup then I should be able to check this).

- Determine amount of offset required to prevent front wheels from fouling suspension bars on full steering lock; I’ll have some wheel spacers made front and back (additional 10 mm would probably solve the problem?) once I know the required offset.

- Fit new pin in passenger’s side door hinge. The old one has fallen out and now the door makes a loud cracking noise when opened due to the spring force in the hinge.

- Check the clutch… the position that the clutch is engaging feels a bit high on the clutch pedal travel (i.e. the clutch pedal is almost fully out before the clutch feels to fully engage). This may be caused by the steep ramp I have to drive up in order to get the park out of the garage where I have the car parked?

If all this is sorted then the car should be running great, plus I can start getting some engine data to play with and use to focus my future upgrading efforts. Plus, once I install the accelerometers then I can get some road dyno results instead of having to go to the dyno all the time.

Thursday, June 21, 2007

New exhaust is coming...

Before playing with the cooling, I want to get the car running how I think it should be with the modification that I've carried out to date. I've also spent a bit of time reading back through this blog and seeing how the car used to perform and I've come to the conclusion that it should be performing better than it actually is at present. That's what prompted the decision to change out the mid section exhaust (coupled with me getting a bonus from work)... I've long suspected one of my cats to be plugged, so changing out the mid section will show whether I'm right or not. The reason I think this is that the car simply doesn't seem to be flowing air at high revs. I know that it's not on the inlet side since the car is running much less losses on the inlet side than a stock car and I know the turbos are in good shape. So the restrictions have to be either on the headers or in the exhaust.

Alternatively, there's something amiss with the timing of the car... and this is something that I'll also have checked out when I take the car to the garage to get the exhaust fitted and to have a few cosmetic maintenance done to the car (changing the bumpers and rolling out a coupe of dents). I'll see if I can also get the data logger installed at the same time.

In the meantime, I've been seeing a few more Maserati around the last couple of weeks. There was a nice looking dark grey Ghibli GT in Den Haag last Friday which looked like the springs had been changed out for lower ones. I also saw a nice 3200 GT in Barcelona a couple of days ago, dark blue with beige leather, exactly what I'm looking for! There's also a silver Ghibli GT that parks outside the royal stables in Den Haag that I see pretty regularly... I think the Ghibli looks good in silver. A couple of weeks ago I also saw a youngish couple drive past in a dark blue Ghibli (again, with what appeared to be shorter springs), again in Den Haag. Seems there's more and more of them around!

Saturday, May 19, 2007

Intercoolers

First was from Buddy at Wereld Auto who informed me that intercoolers from a VW Golf mark IV TDi will fit on the Ghibli, although the one manifold has to be removed and a new one constructed and welded on its place. The good thing about this solution is that it's cheap (these intercoolers can be purchased on ebay for less than €100) and they offer good performance since they're twice the thickness of standard Ghibli units. However, I don't like the idea of having to modify them.

The second option was hinted to me by Jorrit at Auto Forza. He informed me that the intercoolers on the V8 engined Quatroporte is about 30% thicker than the units on the V6 cars. I then happened to stumble upon a picture of a 3200 GT being sold for parts and noticed the intercooler... the location is identical to that of the Ghibli and Quatroporte and the configuration of the ports looked the same.

So I wrote to EuroSpares and enquired as to whether they had any second hand 3200 GT intercoolers and if they could check whether they fitted a Ghibli. They wrote back to inform me that they'd been informed from the factory that the Ghibli intercoolers will fit the 3200 GT (wrong way 'round but by definition, the 3200 GT intercoolers must fit the Ghibli (although the ducting may require a bit of modification)).

Above is the parts schematic from the 3200 GT. Compare the size of the intercoolers with those for the Ghibli in the schematic below.

So I'm tempted to try and source some 3200 GT intercoolers and get Jorrit to try fitting them when he's fitting my new bumber (when it arrives... it's been on order from the factory for about 2 months now!).

As usual... I'll keep you posted of any updates.

Friday, May 18, 2007

Maserati Ghibli V8

I went there to find out more about the KMS, but spent most of the time discussing Ghiblis. He had two in the workshop. one was a MY93 series 1a (but had Mistral style wheels). It was having some problems with a seized turbo, but Buddy has been having trouble trying to source a replacement. So he's working on manifolding a small Garret turbo; designed to flow 180 hp and with a good bearing package, it should be spooled up by 2000 rpm and offer very good low rpm drive-ability (which is what the owner of the car is after).

Buddy says that if he can get the Garret turbo mounted satisfactorily onto the Ghibli's exhaust manifold then he plans to make a kit that will offer a bolt on replacement for Ghibli owners. He also says that by using the Garret turbo, there's lots of scope to play around with compressor sizes to open up tuning possibilities. He thinks he can come up with a kit for around €800 per unit, which is far cheaper than getting a Maserati original part! I'll keep you posted if he managed to pull it off!

OK... the other car was a a very special MY92 Ghibli, but with a Maserati Evoluzione engine and running gear from a Quatroporte, running on a KMS ECU and with larger intercoolers (actually from a Golf Mark IV TDi... they're twice as thick as standard Ghibli units, but the bottom (outlet) manifold needs removing and a new one welding on). Buddy took me for a drive in the car... I've not had that much of a buzz since being in the passenger seat with Top Gear's " The Stig" at the wheel. What a fantastic performing car! The brakes and handling could be improved, but the engine performance is very impressive indeed... the car felt like it had a huge normally aspirated engine, with bags of torque available at low revs... no having to wait for the turbos to spool up like on my Ghibli or having to drop the gears to get the engine revving in it's power band, just stick your foot down and away you go! Buddy's not had it on the dyno recentyl but thinks the performance is around 380 hp with a little under 600 N.m torque. He's set up the KMS pretty conservative so as not to stress the engine too far and make the car very driveable... for example the boost pressure is mapped against throttle position to avoid the big spikes in torque when accellerating out of corners that the car was previously delivering and catching the owner off-guard. It seems that Buddy has a fair bit of track driving experience and he said that the torque spikes were occuring too quick for him to reliably control.

Very, very impressive... kind of gets me tempted to try and source a Maserati V8 and have it fitted in my car! It's a bit tight in the engine bay, but it fits ok and there's actually more ground clearance underneath the car since the V8 has a shallower sump. Plus, since this Ghibli was registered in '92 it doesn't require cats which helps out too.

Regarding the KMS... Buddy still needs to find out if it can run an odd fire engine, so i promised to send on the info that I've acquired and he'll ask the manufacturer. So, lots to report back, but not much yet on the KMS!

Friday, May 11, 2007

ECU Upgrade

The Magnetti Marelli system installed by Maserati is very old compared with today's technology. To put it into context, this system was installed in Ford Sierra Cosworth cars back in the late eighties and early ninetees. The clock speed for this system is around 4MHz. Compare this to a modern laptop or desktop computer, which runs with a clock speed an order of magnitude quicker at 4GHz. In fact, you'd be luck to find a microprocessor that runs less than a hundred times quicker than that utilised in the OEM engine management system.

The effect of this is that the engine management system currently installed in my Ghibli makes significantly less decisions per second than the systems installed on typical modern street cars. Things happen and change very quickly in a car engine, particularly when it's reving at 7000rpm. That's over 100 revolutions of the crank every second, which is 25 detonations per second per cylinder.

The way an engine management system works is by taking a snapshot of the engine, which means recording the values of certain engine parameters at a moment in time by reading the output signals being sent from the various sensors located around the engine. The key sensors on the Ghibli are the inlet air temperature and the inlet air pressure for example. In order for the engine management to make decisions, it needs some reference data. This reference data comes in the form of look-up tables, which is just how people used to make complicated calculations in the days before electronic calculators. These are called maps.

A 2 dimensional map allows you to look up an answer if you know two numbers. Let's say that the inlet temperature is listed across the top row of the look-up table and the inlet pressure is listed along the left column of the table, the answer can be found by drawing a line down from the top inlet temperature value and a line across from the left inlet pressure value. Where the two lines cross is where the answer lies.

The answer tells the engine management system to perform a certain task. However, this answer is only applicable to the moment in time when the two input values were recorded, so if the system is too slow, by the time it carries out the response, it will no longer be applicable... a delayed response.

If there are more sensors, then the management system needs more look-up tables in order to know what decision to make, which takes more time. Also, the decision may require more than one response... for example the amount of fuel that is required and the time at which to ignite the fuel may need to be adjusted. Each additional response takes additional time.

My point here is that the quicker the management system can make decisions and respond, the more effective it is. In the Ghibli, it's obvious that the speed of the engine management system is not optimal, simply by virtue of the fact that TWO management systems are required, one to control the amount of fuel being injected and one to control when the fuel is ignited. So even when the Ghibli was being manufactured, it seems to have been recognised that processing speed was a limiting factor. Therefore, increasing processing speed should have a significant effect on the performance of the engine.

The next issue with the OEM management system is its lack of diagnostic capability. The only real way of determining if the system is making the right decisions is by measuring the performance of the engine, either by having a feel for the car or by sitting it on a dyno. The system does not have an easy way of monitoring what decisions are being made, except by taking the car to a specialist who can tap into the system and monitor what it is doing, which requires a degree of skill, technical knowledge and the appropriate equipment.

Modern management systems however offer a convenient way of monitoring what is happening. They generally have a convenient port into which you can plug a computer and with special software, you can record and review what decisions are being made.

Finally, if you recognise that sub-optimal decisions are being made, you need to be able to change the decision making process, which generally means altering the look-up tables or maps. Again, on the OEM management system, this is not a trivial thing to do and requires removal of the system and some special hardware to reprogramme the memory chips on which the data is stored. Also, the way this data is stored is not very user friendly, as it is stored in a way that is convenient for the microprocessor to read and not the car owner.

The beauty of a modern system is that all these things are possible. With modern software, you programme the data in a form that is easy to understand (using decimal numbers instead of hexidecimal or even binary code required for older systems) using a laptop computer. You can also record data from the engine, review it at a leisurely pace, determine what changes you want to make, update the look-up tables and see straight away the results... without having to go to a chip-tuner!

So, after contacting Van Kronenburg and discovering that they're a Dutch firm (much to my delight, since it means that they're local), I was a bit downheartened that I never heard back from them and it is then that I ordered the PLX Devices R-500 datalogger. However, I subsequently received an email from Buddy at Wereld Auto who informed me that he had been forwarded my enquiry from Van Kronenburg. Buddy is located pretty close to where I live (about a half hour drive) and can install and setup the KMS system on my Ghibli.

Above is a picture of the hardware which would replace the two OEM ECUs. He's given me a quote for fitting the system and I'm going to see if I can integrate the PLX R-500 into the installation to give me realtime feedback on the road. I've a feeling that the lambda probe that came with the R-500 is the same as that utilised by the KMS (a Bosch wideband probe) and I'll also see if I can integrate the Exhaust Gas Temperature (EGT) probe into the KMS, with maybe some feedback to prevent the exhaust gasses getting too hot and damaging the turbos.

The KMS can also control boost pressure, although I'm uncertain if it can tie into the TurboSmart solenoid valve. This would unfortunately make my E-Boost redundant, but I think the KMS would offer greater control over boost pressure with the added advantage of being able to tie in boost pressure maps with fueling and engine load.

I'm waiting to hear back from Buddy with answers to a couple more questions that I have, but if the price is right then I think I might go along with this option. The KMS is certainly much cheaper than MoTec and I like the idea of it being local, since if it stops working then I can go 'round the manufacturer personally to get them to sort it out!

Also, Buddy appears to have worked on a number of Maseratis, including a Ghibli fitted with a V8 engine from a Quatroporte in which the owner wanted the KMS system fitting. He also told me something interesting about the intercoolers from a Golf Mk4 TDi...

Monday, May 07, 2007

Boost contoller sensitivity

I drove to Amsterdam on Saturday evening so got a good opportunity to load up the engine on full boost on the A4, keeping a close eye on the TomTom for cameras. I noticed that sustaining full boost gave the tell tale signs of a too high sensitivity setting, since the pressure gauge needle "wobbled". Before switching off the engine when I arrived at the first port of call, I quickly checked the maximum boost attained during my journey (my boost controller records the highest achieved boost level) and noticed it was high at 1.26 bar.

On one occassion during the drive I noticed a distinct hesitation during accelleration at maximum boost. It lasted a fraction of a second and I'm pretty sure that it was the ECU cutting the fuel supply to the engine after detecting a condition that it considered a bit on the extreme side.

While driving, the boost seemed to be responding very quickly to the throttle, which was nice. However, the wobble at full boost and the pressure spike are not really sustainable if I want longevity from my engine. Therefore, I reduced the sensitivity down to 25 before my next drive. This time, I no longer observed the wobbling needle at full boost, although when I checked the maximum attained boost level at the end of the drive it was still a bit high, indicating that the car was over boosting, I think in the lower gears where the revs ramp up quickly. I've therefore trimmed a little more off the sensitivity to prevent the spike a little, down to a setting of 23.

I very much doubt that this will have an impact on my ultimate power rating from the car, but soon I will be able to get a better idea since my PLX Device R-500 data logger arrived today! I'm not exactly sure when I'll get to install it and will probably have to do so over a few weeks (after first buying a solderer... I've not done any soldering since I was at school so I'm a little anxious about tapping into the car's wiring). I'm looking forward to seeing the data though... should give quite an insight into what's happening with the car...

Sunday, April 29, 2007

Chasing the performance gap

It could be that the boost controller is not responding quick enough with the wastegate control to maintain effective operation of the turbos, but I doubt this since I'd expect to see the boost pressure drop off in this scenario. But I'll try adjusting it nonetheless.

To see if my modifications make and change to performance, I've ordered a G-Meter to do some on the road diagnosis. Hopefully this should arrive in the next couple of weeks and I won't have to make frequent trips to Rica anymore.

I also had a look in the engine compartment yesterday, seeing if there would be space for charge coolers or increasing the size of the intercoolers. Looks like there's a couple of options that I could persue... including something interesting I read about candle wax... But whilst looking I noticed that the hose to the left intercooler has deteriorated quite badly with some nasty crack in the ninety degree elbow. It could be leaking, so I'll ask Jorrit to change it out when I next see him.

Friday, April 20, 2007

Latest dyno results

To be frank, I was a little disappointed with the results. The good news is that, as I suspected, the mid-range torque has improved significantly since the last time I was at the dyno, with power and torque shifting down the rev range and maximum torque now accessible at 4100rpm (where before it was at 5000rpm). This performance correlates directly with the set up of the boost controller, with the boost limit of 1.20 bar achieved at 4100rpm and held steady to the rev limit at 7200rpm.

But what happens after this is a little odd and I'm finding it difficult to determine what is causing it. From 4000rpm onwards, the rate of increase in engine power drops significantly and the torque curve drops away. The result is that the maximum engine power is 30hp less than it was previously, peaking at just under 300hp, where in the past I've had it running at just under 330hp.

I asked Roel at Rica to plot the air/fuel ratio, since I know from the last time I visited them that the mixture was running a bit rich. Indeed, at high revs the ratio was running below 0.8, so after a bit of convincing, I got him to lean it out a little. As you can see from the chart, the ratio is now maintained above 0.8 throughout the high rev range, but unfortunately this made no significant difference to the curves. As a side note, Roel seems reluctant to run the mixture any leaner than this, preferring to err on the side of caution and keep the mixture slightly rich so as not to over stress the engine and to help cooling a little at high revs.

I discussed the curves with Roel and it was his opinion that either the exhaust or the inlet temperature are constraining performance. I've given this some thought overnight and I'm not convinced.

On Enrico's pages there's a chart of a stock Ghibli torque and power curve (the torque is in different units, but just multiply by 10 to get approximate Nm values) which I've attached above. On these curves, there's no sudden change in gradient that I'm seeing on my curves. There seems to be a bit more inertia with my turbos spooling up too... mine have a bit more lag, but once they start spooling up they do so much quicker than the stock ones appear to do.

So, things are looking ok up to 4100rpm. At this stage, the boost controller opens up the wastegates and starts bypassing the compressors and suddenly there's a drop in the rate of power increase and a drop in torque. On the stock curves, the torque stays flat until about 5000rpm and on the Ghibli Cup, this is extended further to 6000rpm with more efficient bearings, as illustrated below.

I'd expect my results to be more akin to the Ghibli Cup ones, since my turbos have roller bearings and are "geared" for greater flowrates and should therefore be more efficient with higher revs. I also have a sports mufflers fitted which should flow better with high revs over the stock car.

For reference, here's an old dyno chart.

You can see that the car used to spool up much slower, which has been rectified by installing a free flowing inlet system and optimising the boost controller settings. However, the car used to produce considerably more power at the top end?

I don't think the inlet temperature can be the cause for the change since nothing has changed that could have increased the inlet temperature unless the efficieny of the intercoolers has changed since last time, which is unlikely. There may be a problem with the exhaust since I know one of the cats is not working and may be causing a restriction? But then I'd expect this to effect performance through the entire rev range, not just from 4000rpm and above?

I was thinking that it was maybe the timing that is out, but this hasn't been changed since the last dyno run. So I'm confused now to explain the difference. Any ideas?

Thursday, April 05, 2007

Bumpers Ordered

In the meantime, I've been looking again at installing a data logger on the Ghibli, probably PLX Devices R-500 unit, pictured below.

I'd like to tie this into some of the Ghibli's electrical devices so that I can get a snapshot of the car's current performance so that I can monitor it and get an early indication of when things are not running smoothly. I'd also like to use the data as a reference for making future alterations to the car, in order to gaugue more accurately the impact that they're having on the performance of the car.

However, I need to find some "current thief" devices that I can use to clamp onto existing electical lines in order to prevent having to break the insulation on these wires to tap into the electrical signals. So I'm doing some research on this... but if anyone has any experience on this I'd love to hear from you!

Thursday, December 28, 2006

Jonny's Mov'it Brakes

Enjoy!

Tuesday, September 05, 2006

Traction control

Of course... this has now got me thinking about how I'd fit this to my Ghibli... something else for me to lay awake at night thinking about! I do think their digital adjuster would look good fastened to the Ghibli's dash though!

The installation would be a bit trickier on my Ghibli though since it doesn't have ABS fitted, so I'd have to fit speed sensors on all the wheels. Wouldn't be too tricky though I think. It would certainly make driving the car in the wet much safer and the with the launch control I suspect that sub 5 second 0-100km/h sprints would be pretty attainable.